True

Value:

It is not possible to determine the true of quantity by experiment

means. True value may be defined as the average value of an infinite number of

measured values when average deviation due to various contributing factor will

approach to zero.

Measured

Value:

It may be defined as the approximated value of true value. It can be

found out by taking means of several measured readings during an experiment, by

applying suitable approximations on physical conditions. Now we are in a

position to define static error. Static error is defined as the difference of

the measured value and the true value of the quantity. Mathematically we can

write an expression of error as, dA = Am - At where, dA is the static error Am is measured value and At is true value. It may be noted that the absolute value of error cannot be determined as

due to the fact that the true value of quantity cannot be determined accurately. Let us consider few terms related to errors.

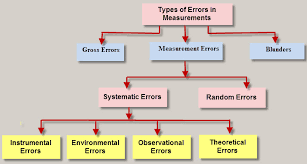

Types of Errors:

Basically there are

three types of errors on

the basis; they may arise from the source.

Gross Errors:

This

category of errors includes all the human mistakes while reading, recording and

the readings. Mistakes in calculating the errors also come under this category.

For example while taking the reading from the meter of the instrument he may

read 21 as 31. All these types of error are come under this category. Gross

errors can be avoided by using two suitable measures and they are written

below:

1. A proper care should be

taken in reading, recording the data. Also calculation of error should be done

accurately.

2. By increasing the number of

experimenters we can reduce the gross errors. If each experimenter takes

different reading at different points, then by taking average of more readings

we can reduce the gross errors.

Systematic Errors:

In order to

understand these kinds of errors, let us categorize the systematic errors as

Instrumental Errors:

These errors may be due to wrong construction, calibration of the measuring instruments. These

types of error may be arises due to friction or may be due to hysteresis. These

types of errors also include the loading effect and misuse of the instruments.

Misuse of the instruments results in the failure to the adjust the zero of

instruments. In order to minimize the gross errors in measurement various

correction factors must be applied and in extreme condition instrument must be

re-calibrated carefully.

Environmental Errors:

This

type of error arises due to conditions external to instrument. External

condition includes temperature, pressure, humidity or it may include external magnetic

field. Following are the steps that one must follow in order to minimize the

environmental errors:

·

Try

to maintain the temperature and humidity of the laboratory constant by making

some arrangements.

·

Ensure

that there should not be any external magnetic or electrostatic field around

the instrument.

Observational Errors:

As the name suggests these types of errors are due wrong observations. The wrong

observations may be due to PARALLAX. In order to minimize the PARALLAX error

highly accurate meters are required, provided with mirrored scales.

Random Errors:

After calculating all systematic errors, it is found that there are

still some errors in measurement are left. These errors are known as random

errors. Some of the reasons of the appearance of these errors are known but

still some reasons are unknown. Hence we cannot fully eliminate these kinds of

error.

0 comments:

Post a Comment